Not every bit of the produce can reach either the market or the food processing industry. Despite ongoing efforts to enhance production, the main challenge we face is the STORAGE of these perishable items.

Are you in the business of preserving perishable goods? Are you storing food, pharmaceuticals, or other temperature-sensitive products? It is important to understand the significance of maintaining optimal temperature levels. A properly constructed cold storage facility is a necessity. It is where the cold storage room plays a vital role. These specialized spaces regulate temperature, guaranteeing that certain items or substances are kept at the required temperatures. They are revolutionizing the business with their excellent storing & preserving capacity.

Factors to Consider Before Constructing a Cold Storage:

Several factors need to be considered before embarking on constructing a cold storage room or refrigeration room.

The initial consideration pertains to the dimensions and arrangement of the storage area. Evaluate your storage needs, including the quantity and nature of the items to be stored. It will be an aid in determining the most suitable size and layout for maximizing space utilization.

Deciding the size of the chambers in cold storage rooms or refrigeration rooms is also essential. It is so because the larger chambers allow easier control of temperature and the relative humidity level. Apart from that you should make storage space usable in a better way.

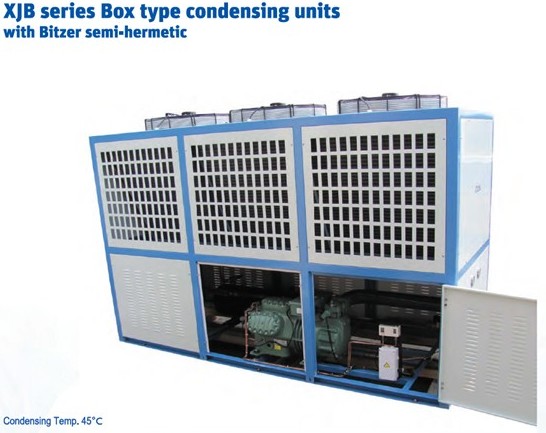

The cooling system serves as the core of a refrigerated chamber. It is crucial to ensure the right and safe refrigeration equipment is in place when constructing a cold storage room. Compressors, generators, condensers, industrial racks, and humidifiers are essential devices for any cold storage room. The system should be designed to maintain the required temperature range consistently. Energy efficiency and reliability should be taken into consideration while selecting the cold storage room.

The location of the cold storage room is another important factor to consider. Local climate conditions, proximity to transportation routes, and the availability of utilities like electricity and water should be taken into account. Adequate infrastructure and accessibility are vital for the smooth operation of the facility.

Proper insulation is necessary to keep the desired temperature inside the cold room and prevent the escalation of energy costs. Common insulation materials such as polyurethane, polystyrene, or mineral wool are the perfect option. The flooring of the cold room should withstand low temperatures and moisture. It should be made from materials whose maintenance & cleaning is easy.

Lighting in the cold room should be designed to ensure safety and visibility while minimizing heat generation. Energy-efficient LED lights are perfect for low heat output and extreme temperature efficiency!

You must need a constant and uninterrupted power supply! Hence cold storage facilities must have reliable backup systems in place. Professional cold storage room manufacturers, such as Africhill, understand the importance associated with power outages, equipment failures, and natural disasters. They employ backup power generators and adhere to emergency protocols. They ensure uninterrupted operations.

Africhill, is a leader in the cold storage & refrigeration room industry. They offer cutting-edge designs tailored to meet your specific requirements. Regardless of how large or small your cold storage room needs to be, they help you with the assistance from planning through execution. To inquire about or any assistance for projects, call Africhill on +27 (0) 11 979 1885 or visit https://africhill.co.za/!

No comments:

Post a Comment